As Metis, We Serve in 11 Different Sectors

HVAC

Pharmaceutical

Aerospace & Defense

Food & Seed

Paint & Chemical Industry

Ceramic & Glass Industry

Transportation & Automotive

Electronics & Nanotechnology

Industrial Fermentation

Other Sectors

HVAC

Cleanrooms are critical areas that ensure the protection of products and samples by purifying them from airborne particles. Cleanrooms that require biological safety are more critical areas where the protection of personnel and the environment is added in addition to the product. Air used at high flow rates in all these environments becomes a very valuable and expensive air when energy factors are added.

Metisafe HEPA fan modules and HEPA fan filter systems, suitable for every industry, have superior technological solutions with their engineering designs that increase energy efficiency by multiples. Compared to conventional solutions, Metisafe products with integrated air conditioning module provide device depreciation within an average of 5 years only thanks to energy savings.

One of the most important issues to be overcome in HEPA filtered ventilation systems is noise. In addition to the noise level, which has been reduced to a level superior to its counterparts with original mechanical designs, Metis has also included active noise control systems among its technologies. Thanks to the Heliosis microbial rapid detection systems being developed in Metis molecular research laboratories, early biohazard warning modules that can perform online monitoring in ventilation systems are in the development stage.

Pharmaceutical

In Metis Biotechnology laboratories, all laboratory studies and developments, including preclinical In-Vivo molecular imaging, from the design of the target molecule or organic structures that can bind to the target molecule, to the analysis and measurement, can be performed.

Pharmaceutical and vaccine production facilities, storage areas and warehouses are areas that should be kept very clean and used hygienically due to the nature of the product and production processes. In the process of drug and vaccine production, from raw materials to packaging, there are stages where raw materials or intermediate products must be opened. The places where these stages take place are very critical areas where additional precautions need to be taken besides the clean environment of the factory.

In addition to the production of raw material weighing room, raw material Containment Booth by Metis Biotechnology, Air Shower, Air-Lock units used in personnel transitions between D, C, B level critical areas, and Pass-Box Metis product range used in material transfers between these areas.

Areas used in production and test studies with cancer drugs are critical clean areas that provide secondary protection with modular BSL-3 air models developed with Metis R&D projects.

It is a technology developed original to Metis, with years of work in the design and production of a very sensitive and critical production area with a device logic.

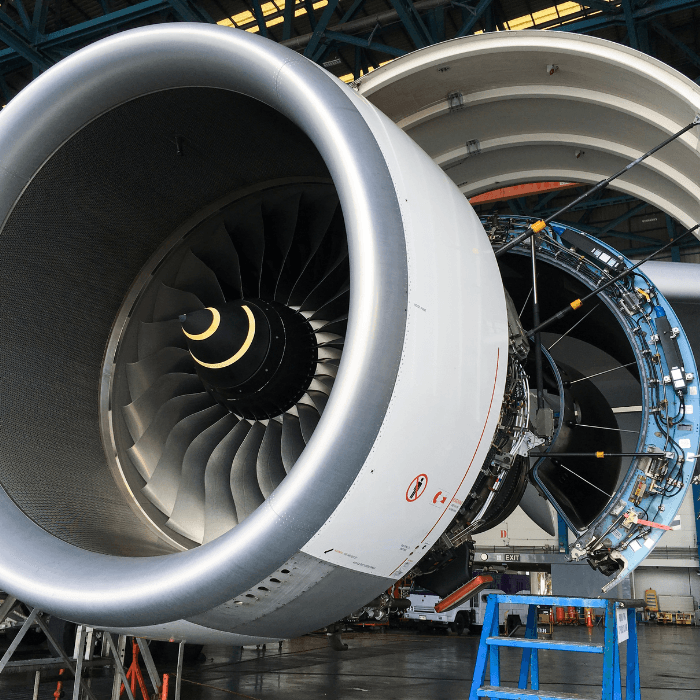

Aerospace & Defense

In the defense and aviation sector, where sensitive optical and electronic devices are used, production and maintenance and repair lines are used in critical clean areas. In the Metis product portfolio, there are solution options ranging from portable air cleaners to improve the cleaning quality of existing spaces, from box-in-box solutions to modular clean room modules.

There are biological detection test kits and devices developed by Metis Molecular Laboratories for NBC (Nuclear, Biological, Chemical) defense technologies.

Among the strategically important national biological defense facilities, the modular facilities with a high biological safety level (BGS-3 and BGS-4), unique to Metis Biotechnology, are designed like the whole facility device with original designs. Vibration resistance is important as it affects the performance of high BGS facilities after use or natural disasters. Thanks to this technology, mobile BGS high laboratories on Metis Trucks or connected to tractors provide superior security.

Food & Seed

Maintaining herbal purity is important for a reliable and sustainable agriculture industry. Primary protection for the prevention of airborne transmission in seed manipulations is possible by providing Laminar Flow Cabinets and secondary protection clean room environments. The products developed by Metis Biotechnology using air flow and directing technologies are noise-controlled and ergonomic COMFORTABLE designs for long-term work as well as energy efficiency.

DNA preparation and PCR amplification kits for GMO analysis are produced and laboratory accreditation is provided by giving trainings.

It is a modular product that fully meets the GMO analysis laboratory validation requirements developed by Metis. From sample acceptance to analysis and reporting room, GMO analysis facilities are a top class solution for institutions with a sense of quality and safety.

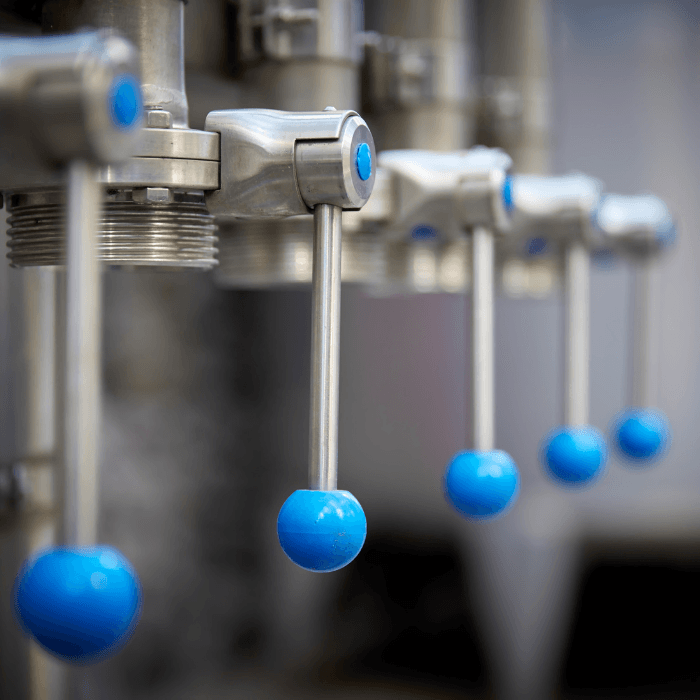

Food filling units are the most risky part where the product needs to be protected with air cleaning. Zero leakage HEPA fan filter units, which extend the shelf life of food developed for food facilities, are produced with high performance and quality while maintaining the market reliability of the brands.

Paint & Chemical Industry

Protecting the environment and personnel from hazardous chemicals in air and ventilation, developing systems that can take warning and protective measures are among the areas of expertise of Metis.

Ex-Proof (Explosion Proof) fume hoods used in fields such as crimonology and petrochemistry, where highly flammable and volatile materials are studied, from fume hoods where toxic chemicals are trapped, macroscopy cabinets for pathology laboratories with serious odor and toxicity problems, as well as CFD analysis and advanced air flow techniques It protects the user from heavy and light gases. Acid Scrubber units, which minimize the damage to the environment, can be integrated into these devices.

Monoblock Industrial Ceramic Trays, developed by Metis with years of work, have a chemical resistance level that few brands in the world have achieved.

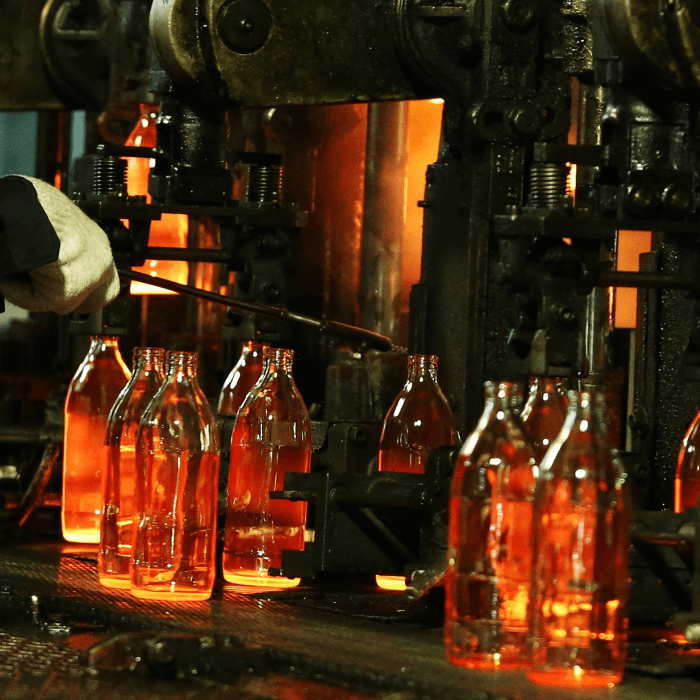

Ceramic & Glass Industry

With Metisafe air showers, a controlled and clean environment is maintained in personnel and material transfers in critical production lines of glass and sensitive ceramic production facilities, where dust affects the product negatively.

Transportation & Automotive

Biological materials developed in the Metis molecular research laboratory find use in all areas where composite technologies are used. One of the projects that have been successfully implemented is the biopads, which are being developed for fast rail systems, which are being carried out jointly with the Bor Institute. Surface coating materials and synthetic biological resins continue to be developed under the Biocombo brand.

Electronics & Nanotechnology

The electronics sector, where sensitive micro-scale productions are made, and nanotechnology facilities where very sensitive products are developed require advanced air cleaning and control. With its box-in-box solutions, Metis produces these very critical areas with device logic. With the integrated Class 100 laminar flow cabinets, the needs of these facilities are met in the upper class without losing their performance for years.

Industrial Fermentation

Industrial Fermentation

Other Sectors

In the Metis molecular research laboratory, there are many raw materials, intermediate product biocomposite R&D and prototype development available to all industries and society, with combinations of biological and nanotechnological production techniques. Organic Molecule Purification is another area of expertise of Metis. Environmental protection and pollution stimulating test and monitoring devices such as online water contamination monitoring and purification of biological wastes are developed with biological active substances developed specifically for the target substance.